Dark Factory Simulation via Factory IO

Project Overview

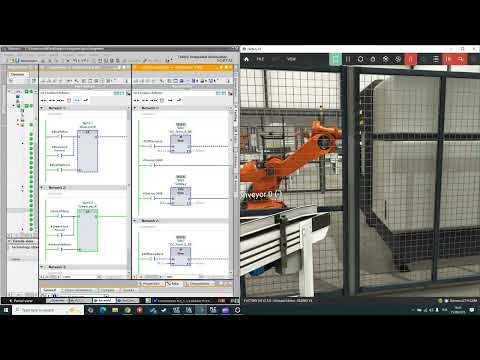

The main goal of this project is to create a fully automated “dark factory,” where production lines, inventory, and even billing processes are managed autonomously. Building on my work with Factory I/O.

A Factory I/O simulation to demonstrate the concept of a dark factory, where industrial processes such as material entry, automated billing, and production management were fully integrated.

Next Steps

Next phase of this journey: bringing Siemens PLC data into the cloud to enable real-time monitoring and analytics.

Objectives

Build a fully autonomus factory simulation with Factory I/O

Create an effective TIA Portal program that ensures safety and efficiency

Extend the digital factory concept by integrating TIA Portal PLC data with cloud services.

Enable live data visualization in Power BI for better decision-making.

Build a scalable foundation that can be applied to real manufacturing environments.

Tools & Techs

Siemens TIA Portal & PLCSIM Advanced → PLC logic design and real-time simulation

Factory I/O → 3D simulation of production processes

OPC UA → standard communication bridge between PLC and external systems

Python (opcua, pyodbc) → middleware for data collection and SQL integration

Azure SQL Database → secure cloud-based data storage

Power BI → visualization and analytics layer

Explore the full source code on GitHub. You can download TIA Portal , Factory I/O programs , run the project locally, and test it yourself. And do not forget to give me a feedback !

Onto Next Steps : PLC to Power BI Integration

Latest step in this project was extending the digital factory by connecting Siemens PLC data directly to Power BI. This integration allows real-time monitoring of production processes, enabling better insights, faster decision-making, and a stronger link between the shop floor and management level.

Check out the video. I explained everything step by step !